Essential Tips for Choosing a Nonwoven Laminating Machine?

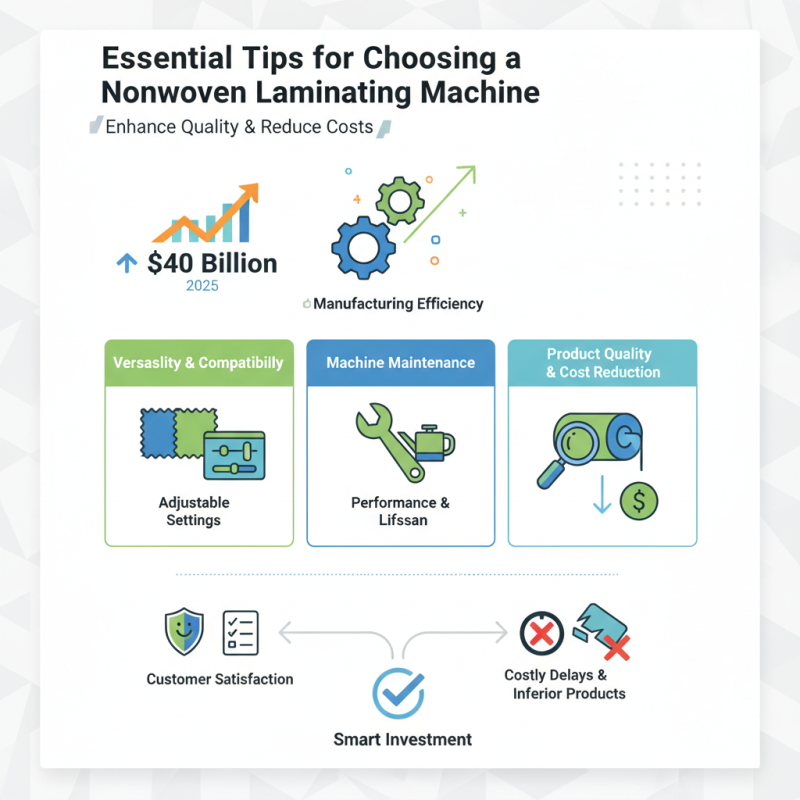

Selecting the right nonwoven laminating machine is crucial for manufacturing efficiency. The nonwoven fabric market is projected to reach $40 billion by 2025. This growth signals a rising demand for advanced laminating solutions. Companies need machines that enhance product quality and reduce production costs.

When evaluating options, consider the machine's versatility and compatibility with various materials. Reports indicate that machines with adjustable settings lead to better outcomes in diverse applications. Many manufacturers overlook machine maintenance, yet this can drastically affect performance and lifespan.

Investing in a solid nonwoven laminating machine is vital. The right choice impacts not only production efficiency but also customer satisfaction. A misstep here can lead to costly delays and inferior products. Proper research and consideration of key factors will pay off in the long run.

Understanding Nonwoven Laminating Machines and Their Applications

Nonwoven laminating machines play a crucial role in various industries, including textiles, packaging, and medical sectors. These machines bond multiple layers of nonwoven fabrics, enhancing strength and durability. According to recent industry reports, the global nonwoven fabric market is projected to reach $50 billion by 2026. This growth highlights the increasing demand for efficient manufacturing processes.

Understanding the functionalities of these machines can be complex. Factors to consider include speed, bonding methods, and operating costs. Some machines utilize thermal lamination, while others employ adhesive methods. The choice significantly affects product quality. A report from TechSci Research indicates that machines with higher bonding efficiency can reduce waste by up to 20%. However, balancing cost and efficiency can be challenging for manufacturers.

Many companies struggle with selecting the right nonwoven laminating machine. Some prioritize cost over performance, which leads to suboptimal results. Poor machine choice can lead to increased downtime and waste. Additionally, not all machines handle various materials well. Manufacturers must assess their specific needs to avoid these pitfalls. Inadequate research may result in unexpected challenges down the line.

Essential Tips for Choosing a Nonwoven Laminating Machine

The chart above illustrates key specifications and considerations when selecting a nonwoven laminating machine. These metrics include speed, power consumption, weight, price, and annual maintenance costs, providing essential insights for decision-making in machine procurement.

Key Features to Consider When Selecting a Nonwoven Laminating Machine

When selecting a nonwoven laminating machine, consider key features that meet your production needs. Look for the machine's speed, as this directly impacts efficiency. A faster machine can handle larger volumes. However, high speed can sometimes compromise quality. Balance is crucial.

Pay attention to the materials the machine can handle. Some machines work well with specific nonwoven fabrics while struggling with others. It is important to check compatibility. This ensures a smooth production process. Evaluate how easy it is to change settings for different materials. An intuitive interface can save time.

Don’t forget about maintenance requirements. A machine that seems reliable now may require frequent repairs down the line. Ask about service options and parts availability. Investing in a machine with support can save headaches later. Understand that no machine is perfect. It's wise to consider your unique production situation carefully.

Essential Tips for Choosing a Nonwoven Laminating Machine

| Feature | Description | Importance | Typical Range |

|---|---|---|---|

| Speed | Measured in meters per minute; indicates how quickly the machine can process materials. | High speed increases production efficiency and lowers operating costs. | 10-100 m/min |

| Material Compatibility | Ability to handle various types of nonwoven fabrics. | Ensures versatility for different production needs. | PP, PET, SMS, etc. |

| Heat Control | Precision in temperature settings for lamination processes. | Improves adhesive bonding and overall quality. | Variable, up to 200°C |

| Roller Configuration | Number and arrangement of rollers affecting lamination pressure. | Influences the durability of laminated products. | 2 to 5 rollers |

| Automation Level | Degree of automation from manual to fully automated systems. | Impacts labor costs and production speed. | Manual, Semi-Automatic, Full Automatic |

| Maintenance Requirements | Ease of upkeep and servicing of the machine. | Reduces downtime and increases longevity. | Weekly, Monthly, Yearly |

Evaluating Production Capacity and Speed Requirements

When evaluating production capacity and speed requirements for a nonwoven laminating machine, it's crucial to assess both current and future needs. Industry reports indicate that production speeds can vary significantly, ranging from 30 to 180 meters per minute. Understanding your workflow will help you find the right speed. For example, high-volume manufacturers often require machines that can operate at the upper end of this range.

Tip: Identify the typical order size you handle regularly. Machines should be capable of handling larger batches to minimize downtime. Consider also the types of materials you will be laminating, as this impacts speed and effectiveness. Nonwoven textiles, for example, may require different handling than conventional materials.

Additionally, fluctuating market demands might impact your capacity planning. Some reports suggest that flexibility in machine settings can increase overall productivity. Machines with adjustable speeds allow for adaptability in various projects. Reflect on your ability to pivot. If your production process is rigid, it may limit potential growth or adaptation to market changes.

Assessing Material Compatibility and Quality Standards

When selecting a nonwoven laminating machine, assessing material compatibility is crucial. The right machine should handle various materials, including polypropylene, polyester, and recycled fibers. According to recent industry reports, improper material compatibility can lead to increased production costs, which can rise by as much as 30%. This emphasizes the need for thorough testing of materials before making a purchase.

Understanding quality standards is equally important. Nonwoven laminating often requires adherence to specific regulatory guidelines. For instance, healthcare applications demand stringent compliance with ISO standards to ensure safety and performance. Manufacturers should evaluate whether the machine can consistently meet these standards, as failure could result in significant losses.

Tip: Always request sample runs. This provides hands-on evaluation of the machine’s performance with your specific materials. Another tip is to consider the flexibility of the machine. A versatile machine may be a better investment than one best suited for a single purpose. Reflect on your long-term production goals. In some cases, investing in a higher-quality machine may yield better returns despite higher initial costs.

Budget Considerations and Cost-effective Options for Purchase

When considering a nonwoven laminating machine, budget plays a significant role. The cost can vary greatly. A basic machine may run around $20,000. Advanced models can exceed $100,000. Therefore, it is vital to evaluate your production needs. A detailed market report indicates that over 60% of manufacturers seek cost-effective solutions. They focus on machines that balance quality and price.

Look for features that offer value. Automated controls and energy efficiency can reduce long-term operating costs. Interestingly, many new entrants overlook maintenance costs. A poor choice can lead to increased downtime. You might save upfront but pay dearly later. Reports show that maintenance can account for up to 30% of total ownership costs.

Consider the option of purchasing used machines. They can be significantly cheaper. Just ensure they meet your quality standards. Often, used machines still come with warranties. This can offer peace of mind while saving money. Explore leasing options as well. Many factories find it a flexible alternative that aligns with budget constraints.