What is the Best PU Foam Lamination Machine for 2026?

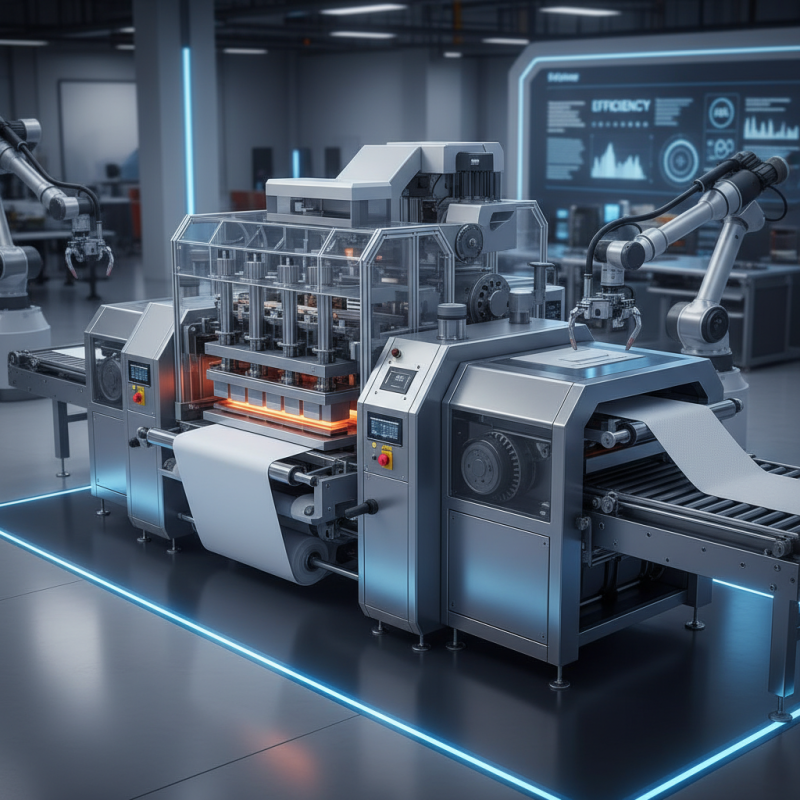

In the ever-evolving world of manufacturing, the PU foam lamination machine plays a critical role. It is crucial for various industries, from automotive to furniture. Choosing the right machine for 2026 requires careful reflection.

Recent advancements offer a variety of features. Factors like efficiency, versatility, and ease of use must be considered. While some machines promise speed, they may lack reliability. It's important to evaluate not just the specifications, but also real-world performance.

Many manufacturers face challenges in selecting the best PU foam lamination machine. Misjudging operational costs can lead to financial strain. Selecting a model based solely on trends may not yield the best results. It's essential to balance innovation with proven functionality. Ultimately, the decision should align with specific business needs and future goals.

Overview of PU Foam Lamination Machines: Key Features and Specifications

PU foam lamination machines play a vital role in various industries. They are essential for producing laminated products, offering strength and durability. When choosing the best machine, focus on several key features.

First, consider the machine’s capacity. The production speed and material thickness are crucial. A good machine should handle different foam types efficiently. Look for models with adjustable settings for flexibility. Another crucial aspect is the lamination technology used. Hot melt or water-based adhesive options are common. Each has its pros and cons, impacting production and final product quality.

Pay attention to user interface and maintenance needs. A user-friendly control panel can streamline operations. However, ease of use can vary widely. Regular maintenance is necessary, yet some machines may require more attention than expected. Evaluate if technician support is available. This can influence your overall experience and productivity. While some machines promise high efficiency, they might fall short in real-world applications. Always reflect on these aspects before making a decision.

What is the Best PU Foam Lamination Machine for 2026?

| Model | Max Working Width (mm) | Production Speed (m/min) | Power Consumption (kW) | Weight (kg) | Features |

|---|---|---|---|---|---|

| PU-2026A | 1500 | 30 | 15 | 500 | Automatic cut-off, Digital control panel |

| PU-2026B | 1800 | 35 | 18 | 600 | Touchscreen interface, Quick change roll system |

| PU-2026C | 1600 | 28 | 14 | 550 | Energy-efficient, Noise reduction technology |

| PU-2026D | 2000 | 40 | 20 | 650 | Packing integration, Remote monitoring |

Market Trends and Consumer Demands for PU Foam in 2026

As we move towards 2026, the demand for PU foam is expected to evolve significantly. Market analysts predict a growth rate exceeding 5% annually. This trend is mainly driven by the rising need for lightweight materials in the automotive and furniture industries. Companies are increasingly adapting to consumer preferences for sustainability, leading to the development of eco-friendly PU foams.

Moreover, recent data indicates a shift in buyer behavior. Consumers are becoming more quality-conscious and willing to pay for superior products. Reports show that 70% of buyers now prioritize durability over price. As a result, manufacturers must focus on enhancing product performance while maintaining cost-effectiveness.

Supply chain dynamics are also changing. Shortages in raw materials have impacted production timelines. Approximately 60% of manufacturers report facing delays. This introduces challenges in meeting consumer demands promptly. Companies will need to rethink their procurement strategies. Attention to these evolving trends is crucial for businesses looking to succeed in the competitive PU foam market.

Top Brands and Models of PU Foam Lamination Machines by Industry Experts

When considering the best PU foam lamination machine for 2026, several top brands and models stand out, according to industry experts. A recent report highlighted that the demand for efficient lamination machines is increasing by approximately 15% annually. This growth is driven by industries focusing on high-quality foam production. Manufacturers need machines that not only perform well but also have robust features.

Analyzing the specifications, machines with a speed capacity of 10 meters per minute are gaining popularity. In addition, they require less maintenance, which is crucial for many businesses. The right machine can minimize production costs. However, some models have reported issues with inconsistent lamination thickness. This inconsistency can lead to wasted materials and time. Manufacturers are seeking solutions for these flaws.

A study found that 30% of companies experienced delays due to equipment malfunctions. Finding a reliable machine is vital. As manufacturers evaluate their options, attention to detail becomes crucial. Factors to consider include machine versatility and energy efficiency. Ultimately, the right PU foam lamination machine can greatly enhance production processes, but caution is necessary. Not every machine meets the industry's rigorous standards.

Efficiency Metrics: Evaluating Performance in PU Foam Lamination Processes

When evaluating performance in PU foam lamination processes, several efficiency metrics come into play. The machine's speed is crucial. Faster machines reduce production time. However, speed shouldn’t compromise quality. A perfectly laminated foam sheet ensures durability and aesthetic appeal. Balancing these factors is essential for manufacturers.

Another important metric is energy consumption. Machines that use less energy can significantly reduce operational costs. Nonetheless, some energy-efficient models may sacrifice performance. It’s vital to scrutinize trade-offs carefully.

Moreover, reliability metrics cannot be ignored. Machines must operate consistently over time. Unplanned downtime can hinder production flow.

Lastly, ease of maintenance should be considered. If a machine requires frequent repairs, it could lead to inefficiencies. Finding the right balance between all these metrics is challenging. Each manufacturer has unique needs. Performance evaluations must align with specific production goals, leading to constant reflection on the best choices.

Cost Analysis: Budgeting for the Best PU Foam Lamination Solution in 2026

When considering the best PU foam lamination machine for 2026, cost analysis is crucial. Buyers often overlook expenses beyond the initial purchase price. Maintenance costs can add up quickly. It's wise to budget for regular servicing and potential repairs. Keep in mind, cheaper machines may lead to higher long-term expenses.

While evaluating options, consider energy efficiency. Machines that consume less power may cost more upfront but save money over time. You should also think about the availability of spare parts. A machine that requires rare components can drain your budget unexpectedly. Factor in training costs for operators as well. Skilled workers may need additional time to learn new systems.

The right PU foam lamination solution must balance price and functionality. It's essential to ask questions and conduct thorough research. Some machines might look great on paper but fail in practice. It's advisable to seek reviews from those who have used them. Think critically about the features you really need. Investing wisely now can avoid costly mistakes later.